In 2024, a local food manufacturer in Chile approached us seeking a mixing solution capable of gentle blending with clean, residue-free discharge. The materials to be mixed included food-grade thickeners such as carrageenan, sugar, potassium citrate, xanthan gum, guar gum, and maltodextrin. These ingredients have relatively low bulk density and are sensitive to temperature during mixing—overheating can cause moisture absorption and stickiness, compromising product quality.

To meet these specific requirements, we recommended the Conical Screw Mixer, which provides controlled, gentle mixing while maintaining temperature stability. After detailed technical communication, the client chose this solution and successfully placed an order.

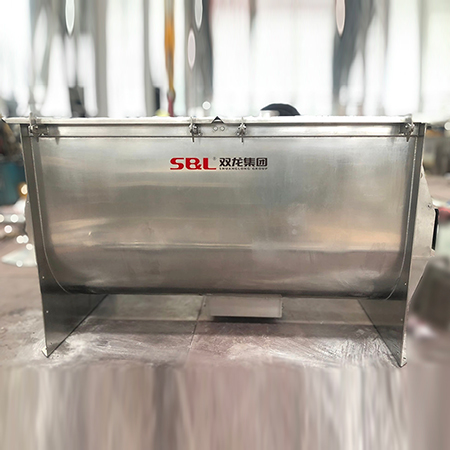

Technical Specifications

- Total volume: 6000 L

- Batch capacity: 2000 kg

- Material: stainless steel 304

- Surface treatment: Food-grade internal polishing Ra ≤ 0.6 µm; external matte finish

- Motor and gearbox: ABB & SEW (enhanced transmission power due to low material flowability)

- Equipped with an integrated weighing system

- Includes a smart control system

Optional Features

- Cleaning access door on the bottom cone for easy maintenance

- CIP system for clients with high hygiene standards

- All lubricants used are FDA-certified food-grade

Other Cases