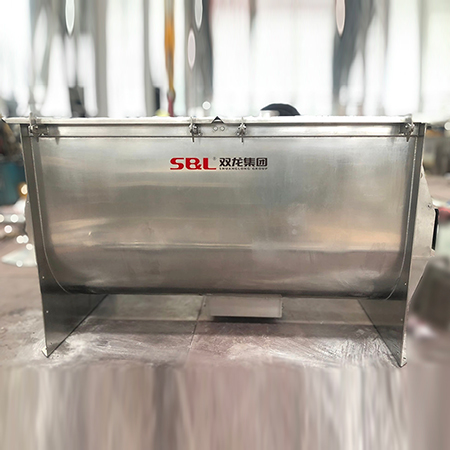

In 2024, Shuanglong received an international order to manufacture a custom 20 m³ plow shear mixer (reactor). After eight months of dedicated engineering design and manufacturing, the reactor was successfully completed and delivered to a customer in Indonesia in October of this year.

This advanced reactor integrates multiple processes—mixing, reaction, drying, and cooling—into a single system. It is primarily designed for blending fatty acids and calcium carbonate, meeting the specialized requirements of calcium soap production.

To meet the operational needs of the calcium soap process, Shuanglong made several key improvements based on the traditional plough mixer design:

- Transmission system engineered to provide the torque demanded during the reaction process

- High-speed chopper equipped with Burgmann mechanical seals and a cooling circulation system

- Reinforced main shaft and plow head design

- External heating/cooling jacket for precise thermal control

- Top-mounted steam discharge device

- Full compliance with ASME pressure vessel design and manufacturing standards

This project started in late 2024. The reactor vessel was designed and manufactured strictly according to ASME standards. Each welding section underwent non-destructive testing, followed by pressure testing and certification of the vessel. After the vessel was completed, the main shaft, agitator blades, discharge valve, and drive system were sequentially installed and thoroughly inspected.

The reactor was successfully shipped and delivered on schedule, receiving high satisfaction from the client for its product quality and performance.