Our client, based in Chile, specializes in producing raw materials for the baking industry, providing comprehensive solutions to bakery businesses across the South American market. In February 2024, they reached out to us online for the first time. Their primary materials include flour, yeast, and other baking ingredients. Initially, the client was undecided between a Plough Shear Mixer and a Vertical Ribbon Mixer.

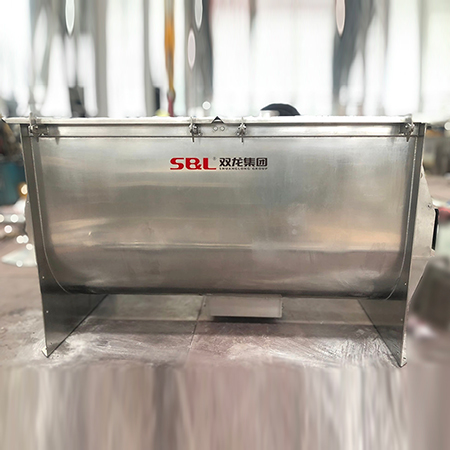

After a thorough assessment of their production requirements, we provided a detailed comparison of both mixer types. Ultimately, they selected our high-efficiency Paddle Mixer, which offered the best performance for their specific needs.

To further optimize the process, we equipped the mixer with a liquid spraying system and dedicated liquid tank, along with CIP spray nozzles to ensure complete removal of residue from the inner chamber. Since the sprayed ingredients tend to clump, we also incorporated a high-speed chopper to effectively break down agglomerates and maintain consistent blend quality.

- Total volume: 1000L

- Batch capacity: 400 kg

- Material bulk density: 0.6–0.7 kg/L

- Material: Full stainless steel 304

- Surface treatment: Food-grade polish (Ra ≤ 0.6μm) on contact parts; matte finish externally

- Motor and gearbox: Reinforced power design due to loading-before-starting requirement

- Chopper speed: 1440 rpm

- Side access door: Included for easy cleaning and maintenance

| Feature | Plough Shear Mixer | Paddle Mixer |

| Mixing time | 5-8 minutes | 8-10 minutes |

| Chopper | included | included |

| Discharge residue | bottom residue | no residue |

| CIP system | included | included |

| Sealing system lifespan | ~6 months | 1.5-2 years |

| Energy consumption | high | low |

| Installation space required | compact | larger space requirement |

| Cleaning access door | included | included |