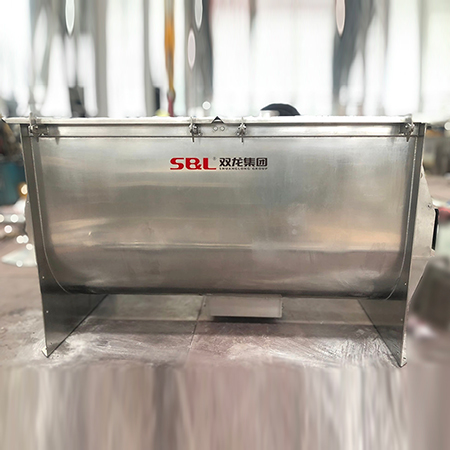

In 2023, the China division of Foodex—a globally recognized innovator in food ingredient development—partnered with us to source a high-performance mixing solution for their factory in Indonesia. Known for its commitment to premium natural and functional ingredients, Foodex required a mixer that could meet the highest standards of safety, reliability, and efficiency.

Before making their final decision, the Foodex team conducted multiple on-site mixing trials at our facility using our 100L Vertical Ribbon Mixer. The trials involved actual raw materials from their product line, and the results exceeded their expectations. Impressed with the performance of our equipment, they selected our solution.

During our in-depth technical discussions, Foodex outlined several stringent requirements that would guide the final equipment design:

As the core equipment for seasoning production, the mixer needed to handle complex formulations containing sugar, salt, MSG, and up to 10% paste-like viscous liquids. Unlike the conventional standards in the Southeast Asian market, Foodex demanded premium, industry-leading specifications from the very beginning:

Material standards- Full food-grade 316L stainless steel

- All contact surfaces mirror-polished (Ra ≤ 0.6μm)

- The surface finish must be flawless—completely free of scratches or dents

- All welds treated with both mechanical and electrolytic polishing after argon arc welding

- Third-party material certification reports must be provided (including spectrometer and factory reports)

- All gear reducers and transmission components must use FDA 21-certified food-grade lubricants

- Equipped with advanced oil sealing system

- Laser calibration ensures mixing paddle and tank clearance strictly maintained at 3–6mm

- Measured 35% improvement in mixing efficiency compared to traditional 8–10mm gap machines

- Coefficient of Variation (CV value) maintained at ≤3.5%, ensuring consistent mixing uniformity

- Specially developed vertical ribbon + integrated mixing system to minimize flavor residue

- All contact surfaces feature no-residue flow design, replacing traditional dead angles caused by bolts in dual-screw mixers

- Standard water rinse (0.5 MPa)

- Alkaline disinfection (1.2 MPa)

- Solvent cleaning (2.0 MPa)

- Motor and control cabinet certified with ATEX II 2G Ex db IIC T4

- All electrical components rated IP68

- Equipped with pneumatic discharge outlet (DN200)

- Total volume: 2000L

- Batch capacity: 800kg

- Material: 316L Stainless Steel

- Surface treatment: Food-grade polished Ra0.6 for contact parts, matte finish for exterior

- Motor and gearbox: International brands ABB & SEW

- Features liquid spraying system

- Equipped with sampling device

- Utilizes PLC control system